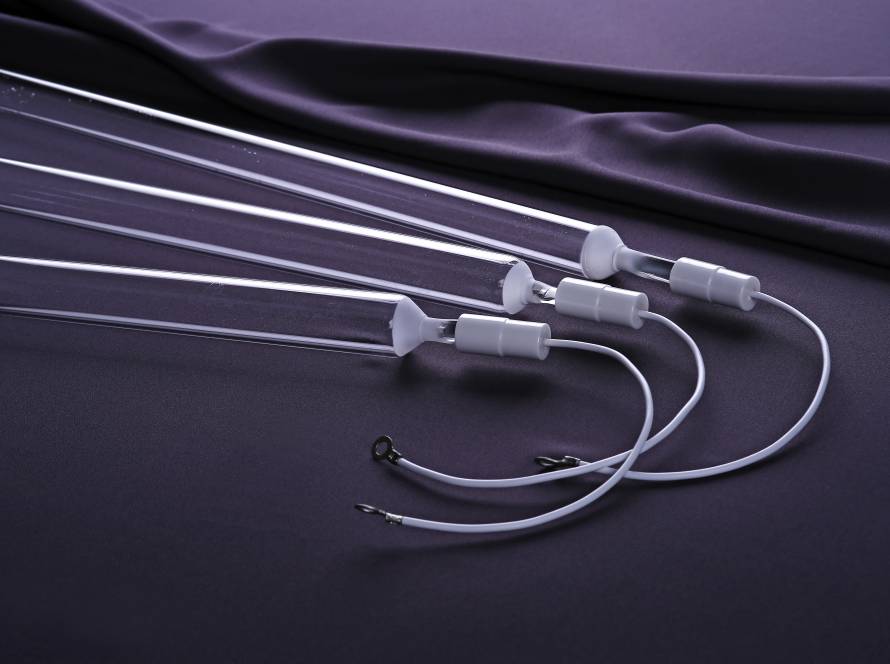

UV LAMP ISSUES AND TROUBLESHOOTING (PART 1)

During operation, UV lamps often encounter certain issues that cause them to stop working or significantly reduce their lifespan. These problems can negatively impact production efficiency, product quality, and lead to increased costs due to frequent lamp replacements. At UVTech, we would like to share with our valued customers some common UV lamp issues and preventive measures to help extend the lifespan of your UV lamps and optimize your system’s performance.

1. Devitrification/Clouding

Issues: UV lamps may become cloudy when white spots appear on the quartz surface, making the lamp no longer clear as it was originally. This clouding effect obstructs the transmission of ultraviolet rays through the quartz glass, reducing curing efficiency. This condition typically occurs after the lamp becomes contaminated, and it is often worsened when the UV lamp operates at excessively high temperatures.

Prevention:

Ensure that the UV lamp is clean before operation and is used in a dust-free environment.

Ensure that the UV lamp operates at the correct voltage and power, and that the UV system is properly cooled.

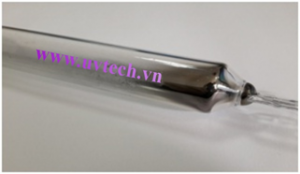

2. Mirror Coating

Issues: When the curing system generates too much cold air that is not evenly circulated along the lamp’s length, it may result in reflective coating buildup (mirroring effect) at both ends of the UV lamp.

Prevention:

The ends of UV lamps are typically coated with heat-reflective materials such as gold, platinum, or white silver paint to retain internal heat. Among these, the white reflective coating is actually the most effective for maintaining optimal internal temperature.

However, when the curing system produces excessive cold air that is not properly and evenly distributed along the full length of the lamp, it can negatively affect performance. It is essential to ensure that the temperature at both ends of the UV lamp remains above 600°C.

Additionally, prolonged operation of UV lamps at incorrect voltage can severely shorten lamp life and reduce efficiency. In such cases, users are strongly advised to seek professional consultation to ensure proper system configuration and safe operation.

3. Bowing/Deformation

Issues: Overheating of UV lamps, often caused by inadequate ventilation or poor airflow in the UV curing system, can lead to the softening of the quartz envelope. As a result, the quartz may sag under its own weight or deform due to internal and external pressure differences.

Prevention:

During operation, the lamp body temperature should not exceed 850°C, and the lamp ends should not exceed 350°C.

Adjust the airflow and cooling around the lamp, and ensure that your cooling system is fully functional and properly maintained.

The UV lamp can be rotated 180° on a weekly basis.

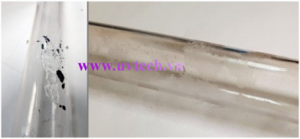

4. External Contamination

Issues: External contamination can occur when the UV lamp is handled directly with bare hands, leaving fingerprints on the quartz surface. Additionally, dust, paper particles, ink residues, or other external contaminants may adhere to the outer surface of the lamp during operation or maintenance. In some cases, poor cooling performance can cause aluminum components—such as the reflector housing—to overheat and melt, dripping onto the lamp surface and leading to serious damage, including pitting or burn-through of the quartz envelope.

Prevention:

Always handle or replace UV lamps only after they have completely cooled down. It is recommended to wear clean cotton gloves during any handling process to prevent contamination.

If the lamp becomes contaminated due to chemical exposure or direct contact with bare hands, clean the affected area thoroughly using alcohol and a lint-free cloth.

There are many other potential issues that may arise during the operation of UV lamps. UVTech will continue to share more insights and preventive measures in the upcoming article: "UV Lamp Issues and Preventive Measures – Part 2."

Thank you!

LIEU QUOC BINH